Company’s thermal hydrolysis process lowers cost of turning raw methane into renewable natural gas.

There was a time when the anaerobic digester was a hot topic because farmers could capture methane from cattle, hogs or poultry to power generators on the farm. Excess power could be sold to the grid. The economics of that power generation has changed, but the value of the on-farm methane may be rising. The key is renewable natural gas, and new tech from an equipment firm is lowering cost of production.

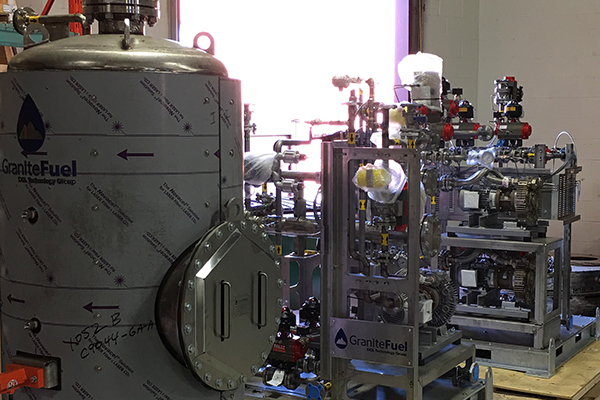

Biogas conditioning company GraniteFuel Engineering, based in Toronto, has developed a new technology that improves the cost effectiveness of the process of turning raw methane into renewable natural gas. That on-farm gas isn’t very clean yet can burn like traditional natural gas if properly processed.

“What we attempt to do is set ourselves apart a bit by innovation,” says Glen Prisciak, sales director at GraniteFuel. “We have a strong research and development department that allows us to do all kinds of neat testing.”

That research has led to a new process that helps clean methane from livestock operations, wastewater treatment plants and landfills more efficiently. The process called thermal hydrolysis can cut the cost to allow more on-site energy production from the farm. The patent for the process is pending, Prisciak says.

Capturing the renewable natural gas potential from all agriculture, landfill and wastewater sources in North America could be used to “displace more than 50% of current natural gas used in the transportation sector,” he notes.

The potential for renewable natural gas is large, but cleaning up that methane so it can be injected into the pipeline takes an investment in processing equipment. A major part of the cleaning process involves removing volatile organic compounds and siloxanes, both undesirable components of “raw” methane. Traditionally, this is done using absorption technology — special media that captures the undesirable components. However, this requires frequent changing of expensive filtering material.

Thermal hydrolysis involves heating the gas to a proprietary temperature, which facilitates breakdown of the bad components and reduces the need for replacing the filtering media. This process also helps protect other parts of the process downstream.

“What we do at GraniteFuel is produce a train of equipment that gets gas from the raw state to the renewable natural gas state,” Prisciak says. “We’re always looking for unique ways to improve the process.”

In any processing operation, small changes in the approach can have valuable impacts in the cost of production. Simply reducing the amount of times the filtering media needs to be changed can be a major cost savings, he notes. And the heat generated by the new approach can be applied elsewhere in the process.

As livestock farmers look at ways to bolster income sources from their operations, they may find methane more valuable. Cutting the cost of converting the raw methane into renewable natural gas can add value. Add in rising interest in renewable natural gas and carbon credits, and more producers will be looking at process chains like those produced by GraniteFuel. You can learn more atgranitefuel.com.

Read the full article in The Seam